The Cove Tasmania is a family-run tourism venture that has evolved from a glamping concept into an award-winning resort. Situated on farmland settled by the family in 1867 and located just five minutes from Devonport, the business originally focused on cattle grazing before transitioning to tourism. The Cove Tasmania now includes a luxury five-star villa and 12 outdoor accommodations, including cliffside chalets and A-frames.

Kim has played a pivotal role in steering the business toward sustainability and emissions reduction. This shift emerged from the realisation that modern travellers expect tourism businesses to be visibly committed to environmental protection and conservation. Visitors to Tasmania have even higher expectations because of the island’s recognition as an ecotourism destination.

The resort’s vision is centred on minimising environmental impact and applying principles of circularity and regeneration to the site and its operations. Efforts to improve resource efficiency are driven by a passion for lifelong learning, with Kim actively exploring alternative solutions and trying new ideas.

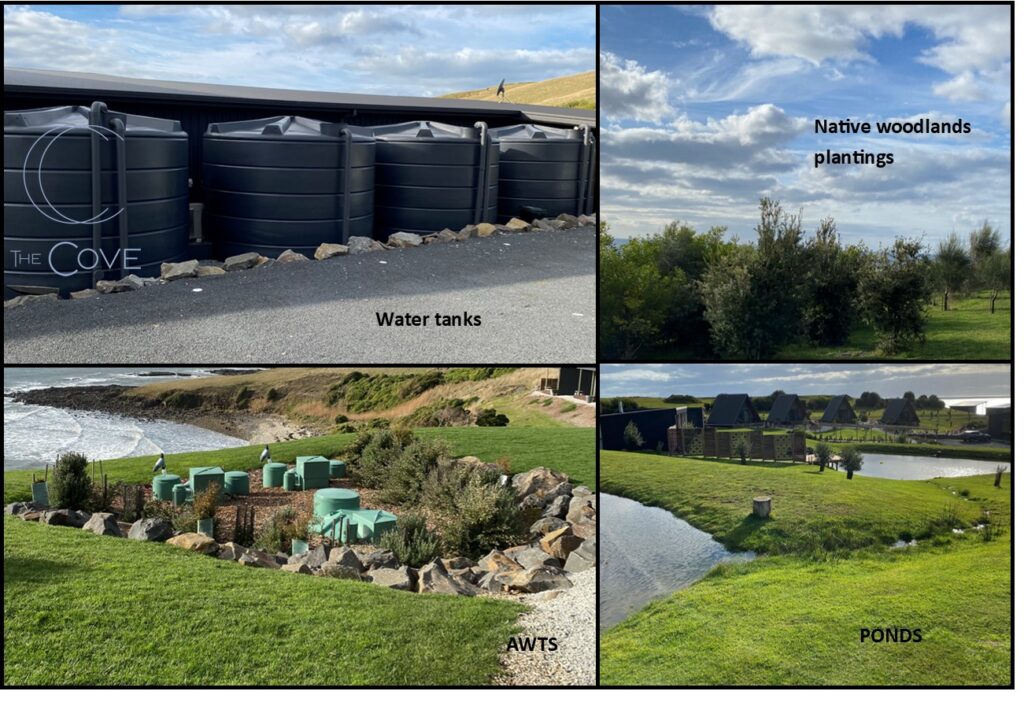

Resource efficiency has been designed into the site with passive features like north-facing double-glazed windows in their accommodation, and investments in infrastructure, such as a comprehensive water management system. The regeneration of native woodland and conservation of local fauna enhances the natural attractions and the visitor experience.

The Cove participated in a pilot emissions reduction program with Tourism Industry Council Tasmania (TICT) and received a comprehensive carbon audit report. Kim’s initial focus during BREP was an opportunity for improvement identified in the report; working with suppliers committed to reducing the emissions associated with goods and services that contribute to the carbon footprint of The Cove.

Kim also explored the feasibility of recommissioning an abandoned ethanol plant. Kim and other businesses in the region source ethanol from the mainland to use as a low-emission alternative to gas for heating. Producing biofuel from potato harvest residues on the farm had the potential to reduce costs and create a local supply of a renewable energy source.

“We’ve been really inspired by some of the solutions being developed in the different sectors that we were exposed to during the program.”

Kim Robinson

Managing Director, The Cove Tasmania

A major service provider for The Cove is a local commercial laundry. Kim contacted the business to ask about their environmental management systems, resource usage and emissions. The laundry was happy to share information and the strategies they have put in place to reduce water and energy use. They also invited feedback and welcomed the opportunity to work together and see how they could contribute to reducing emissions. By having this conversation, Kim has indicated to their supplier the value The Cove places on lowering emissions in their supply chain. This creates an incentive for the supplier to continue improving because they understand that purchasing decisions are no longer made on price alone and lower emissions are a competitive advantage. An added benefit is that this will result in a smaller combined footprint for all businesses in the region that use the laundry service.

Kim’s investigation into setting up the ethanol plant revealed that while there was a potential business case, the initial capital investment and commercial risks were high. It would take resources away from other development projects, including the planned construction of a restaurant already underway. Kim or another family member would need to invest time and effort to learn about ethanol production and drive the project to make it happen. However, there was support in the family for a longer-term plan to produce ethanol for distillation into boutique vodka. This appealed to the family’s entrepreneurial spirit as a unique product that could capitalise on the region’s reputation for producing premium potatoes.

Kim plans to conduct further research into post-harvest potato waste and collaborate with farmers and processors to quantify potential feedstocks for the ethanol plant. Kim is keen to collaborate with research partners or students in a related discipline, who could assist in collecting and analysing data. This will help to refine the business case for establishing a distillery, considering both the costs and logistical challenges, such as collecting and transporting potato harvest residue from local farms. A fully costed business proposal will help the family to reduce financial risk and attract funding.

Alongside these activities, work will continue to reduce emissions across the operations by finalising the acquisition of electric vehicles – and sequestering carbon by incorporating biochar into their gardens and farming operations.

Learning into action

What have you learnt from Kim’s experience that you could put into action in your business? Here are three actions you could take right now:

- Call your biggest supplier and find out what they are doing to lower emissions and reduce their environmental impact.

- Check your eligibility for the TICT Emissions Reduction Initiative.

- Watch our video Sustainable Supply Chains or read related case studies shown right.