The Tasmanian Government

is committed to growing a

climate-ready economy.

Through the Business Resource Energy Efficiency Program (BREP), Renewables, Climate and Future Industries Tasmania (ReCFIT) will work with businesses to:

- reduce emissions intensity;

- adopt innovative practices;

- support businesses to manage financial and climate risks; and,

- strengthen economic and investment opportunities/competitive advantage of Tasmanian small- and medium-sized enterprises (SMEs) in the transition to a low-carbon economy.

Who is BREP for?

Small to medium-sized enterprises (SME)* and Not-for-Profits, with a principal place of operation in Tasmania.

Local councils interested in supporting SMEs and not-for-profits in their local government area are welcome to be involved as important stakeholders.

Business networks are invited to partner with BALT to promote and support the formation of peer learning groups, within their membership.

*For the purposes of the Business Resource Efficiency Program SME is defined as small businesses that employ at least one person and less than 20 people, or medium-sized businesses employing between 20 and 200 people.

Objectives

The objectives of BREP are to:

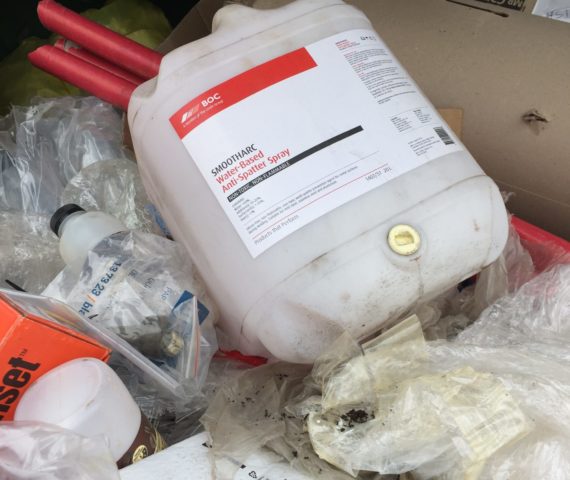

- help Tasmanian SMEs reduce their consumption of resources, minimise waste streams and resultant greenhouse gas emissions;

- reduce operating costs and drive productivity gains; and

- provide SMEs with practical and tailored information regarding ways to improve their resource efficiency.

Program

Exploratory Learning Series

The BREP Exploratory Learning Series showcases Circular Economy (CE) thinking, existing solutions, and emerging technologies from Australia and around the world. Each event presents a keynote speaker on a relevant topic and offers an opportunity for business owners and senior managers to ask questions and explore potential applications in the Tasmanian context. In the latest series, speakers include global leaders in CE strategy, product lifecycle assessment, sustainable design, and new product offerings.

Site visits

A program of site visits to view Tasmania’s waste management systems, including regional organics processing facilities, materials recovery facilities and landfills, plus tours of facilities showcasing resource efficiency strategies and new technologies.

Review Forum

Participants share the outcomes of their chosen project and share lessons learned at a final Review Forum. The 2023 Review Forum was held at Country Club Tasmania in Launceston on 21 September and featured Craig Reucassel from the ABCs War on Waste. Case studies were presented by:

- Frank Strie, Terra Preta Developments

- Christina Giudici, The New Black Biochar

- Kim Robinson, The Cove Tasmania

- Milca Perez, The Reuse Shed

- John Meehan, Mitchell Plastic Welding

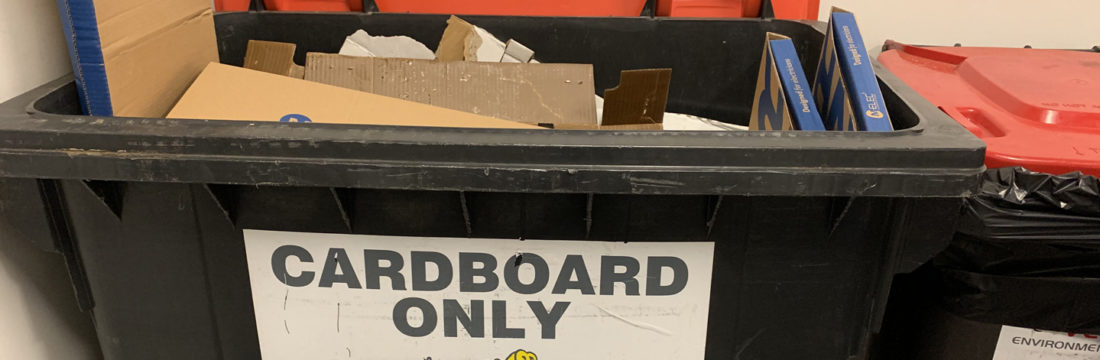

Waste auditing

Participants, or a delegated employee, can participate in an online waste audit workshop, access supporting resources and materials, and use the collective knowledge and experience of the BALT network to validate their auditing practices. The outcomes of waste audits provide opportunities for improvement and support the selection of a suitable project addressing resource efficiency.

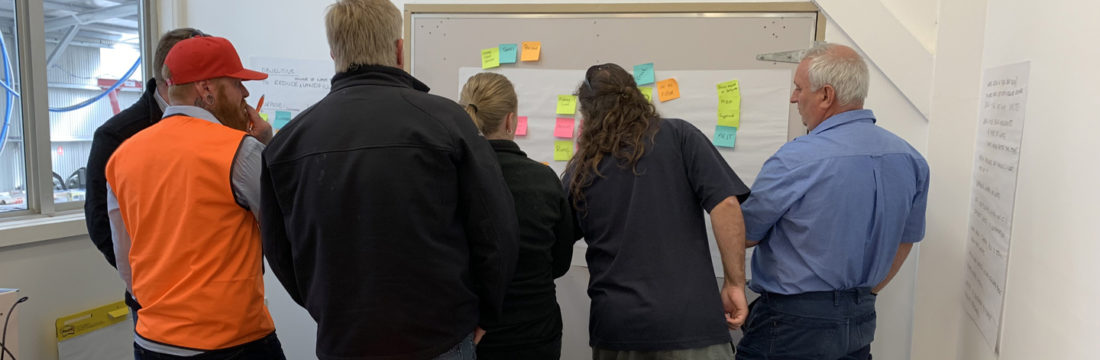

Working groups

Building upon existing networks, working groups meet regularly (online and on-site) to apply collective learning to individual challenges and highlight the interdependency of a circular economy. Meetings are facilitated to encourage collaborative business relationships and joint projects that advance the circular economy and regenerative systems across Tasmania.

Mentored implementation

Participants receive individual mentoring from a qualified facilitator to assist with resource efficiency initiatives. Project examples include:

- elimination of all forms of waste

- product lifecycle assessment

- environmental management systems

- new product development

- supply chain optimisation

Testimonials

“I had really good engagement from staff. Everyone wants to be a part of the solution.”

Anna Robertson

General Manager

Bridestowe Lavender Estate

“I learned a lot from other set members, who had more experience with this type of project.”

Greg Hillier

Cookery Teacher

Drysdale North

“We are very efficient at many things already because stinginess is a waste-fighting super power!”

Karina Dambergs

Cidermaker

Red Brick Road Ciderworks

“I appreciated having people outside my business to help me reflect on my achievements and celebrate successes along the way.”

Fiona Turner

Vigneron

Jinglers Creek Vineyard

“I discovered that we’re not isolated, there are common themes around resource efficiency across businesses and industries.”

Brett Wheldon

Systems Coordinator

CPT Engineering

“Changing our mindset from ‘reducing waste’ to ‘improving quality’ made a big difference.”

Scott Lovell

Owner/Manager

ThinkBig Printing

“A key learning for me was the important part industry plays in reducing waste in Tasmania.”

Phil Stephenson

Chief Production Officer

Nichols Poultry

“Finding a solution for fibre composite waste would be ground-breaking and quite significant. I feel we have come very close.”

Darren Emmerton

Production Manager

Penguin Composites

“Your company must be fully on board, right to the top, before you look at funding options.”

Warren Maney

Manufacturing Logistics and Procurement Officer

Botanical Resources Australia

“Check your waste contracts, don’t just renew them. You may find there is a strong business case for diverting waste from landfill.”

Adam Sutton

Project Manager

pitt&sherry

“It was great to get ideas from other businesses and see some of our ideas adopted by others in the group.”

Bronte Richardson

Programmer

Direct Edge Manufacturing

“Your company must be fully on board, right to the top, before you look at funding options.”

Ray Howe

Production Manager and Plant Engineer

Botanical Resources Australia