Waste auditing

Waste auditing is a critical process for improving sustainability and efficiency. It involves systematically examining resource usage and management practices to identify opportunities for improvement.

Waste auditing is a critical process for improving sustainability and efficiency. It involves systematically examining resource usage and management practices to identify opportunities for improvement.

A sustainable business model integrates principles that reduce waste, encourage reuse, and promote the regeneration of natural systems.

Navigating the financial aspects of transitioning to a circular economy can be challenging for SMEs (small to medium-sized businesses) with limited capital.

Templates Audit Checklist templateWaste Survey WorksheetWaste Survey CalculatorAction_Plan-Gantt_ChartA3 Problem Solving templateCause and Effect WorksheetSet Meeting Agenda templateCompany ProfileRequest for Information templateAudit Report template with guidelinesAudit Plan template Fact sheets Fact sheet – Conducting an auditFact sheet – Lifecycle AssessmentFact sheet – Financing CE InnovationFact sheet – Sustainable Business ModelsFact sheet – Resource EfficiencyFact sheet – […]

LCA helps us understand the complete picture of how a product impacts our planet, allowing businesses and consumers to make more environmentally responsible choices.

These common problem solving tools can be applied to identify root causes and generate ideas for increasing resource efficiency.

Preparing a business case will help you to decide if the cost of improvement is worthwhile and provide justification for others, who need to be engaged for change to be successfully implemented.

Sustainable design principles invite us to rethink the perceived value of a product or service and consider the social, environmental and economic impacts of our design choices.

In a circular economy, we keep resources in use for as long as possible, extract the maximum value from them whilst in use, then recover and regenerate products and materials at the end of each product service life.

The Circular Economy (CE) is an alternative to the traditional linear economy, in which resources are consumed and ‘waste’ is discarded (sometimes described as take, make, use and dispose). In a circular economy, we keep resources in use for as long as possible, extract the maximum value from them whilst in use, then recover and regenerate products and materials at the end of each product service life.

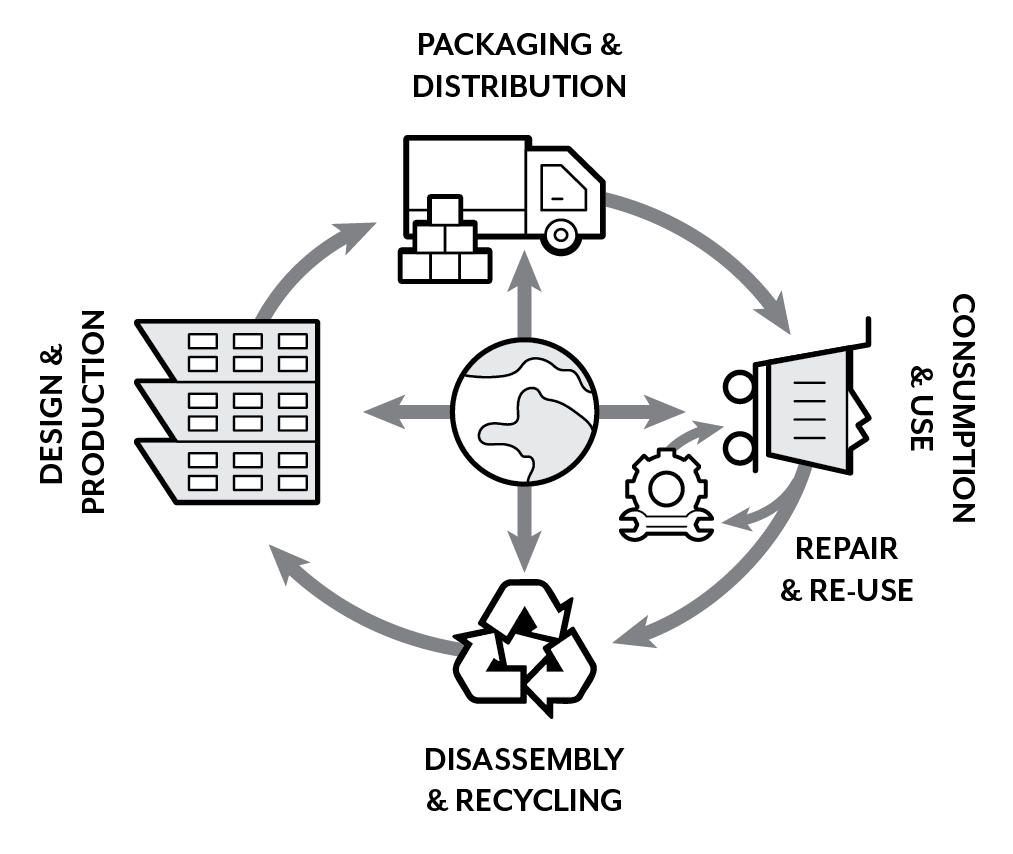

Product/service lifecycle

Resource efficiency promotes the idea of using resources efficiently at all stages of a product or service lifecycle. The ultimate goal we are pursuing is a ‘closed loop’, minimising or eliminating the need for virgin materials and eliminating waste from every stage in the product lifecycle.

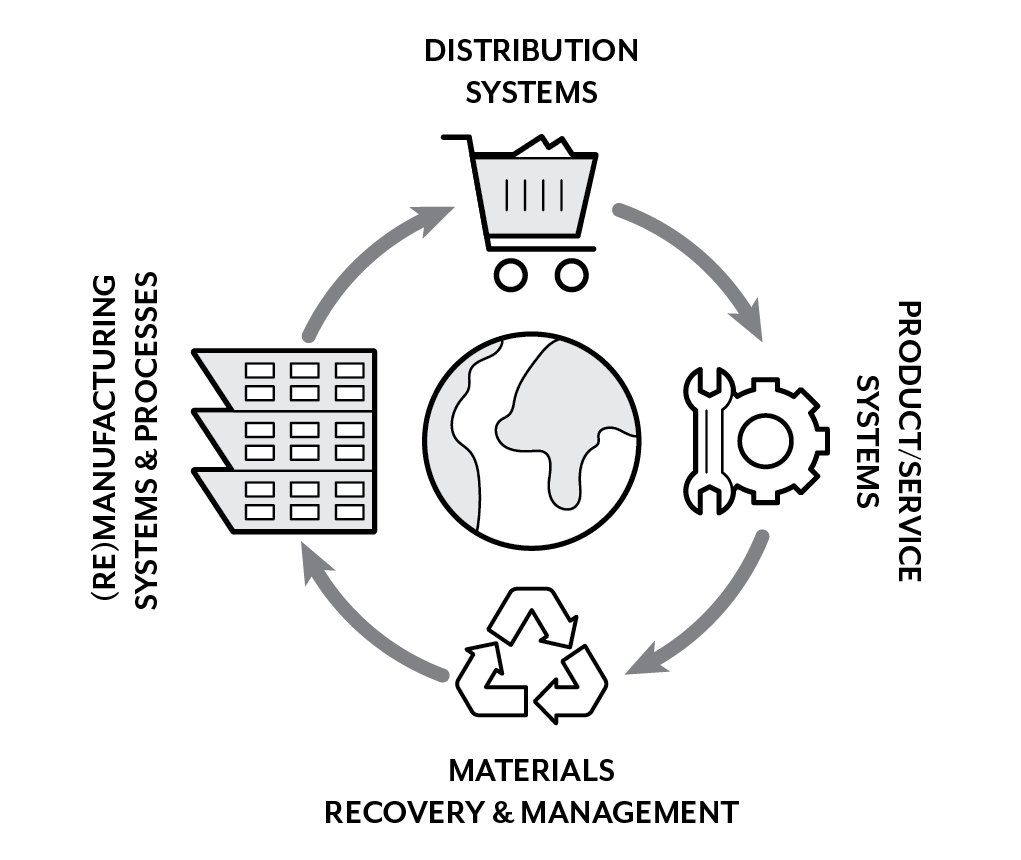

Circular Economic System

The Circular Economy is a ‘closed loop’ economic system that supports resource efficiency. As we reduce the inputs and outputs at each stage of the product/service lifecycle, we need a supporting system for extracting value and retaining resources in the system.

There are a number of things that small to medium-sized businesses can do to increase their resource efficiency and support the development of the Circular Economy in Tasmania.

If there are no recycled options for the materials you use, then choose virgin materials that have established recycling systems and known secondary markets. For example, food safety standards exclude the use of recycled plastics in food production but choosing common plastics like polypropylene and high-density polyethylene will increase opportunities for recycling. For single use plastics, consider compostable materials.

Design your products so that component parts can be easily replaced, repaired or separated for recycling. Think about your business model and pricing strategy – does it support after-sales services like spare parts replacement, repairs or servicing of products to extend their useful life? See our webpage on Sustainable Design for more information.

Make the switch to recycled materials, or products with recycled content. This helps create the demand for recycled materials. For example, if you have products or packaging that include paper or plastic materials, make sure they include at least some recycled content.

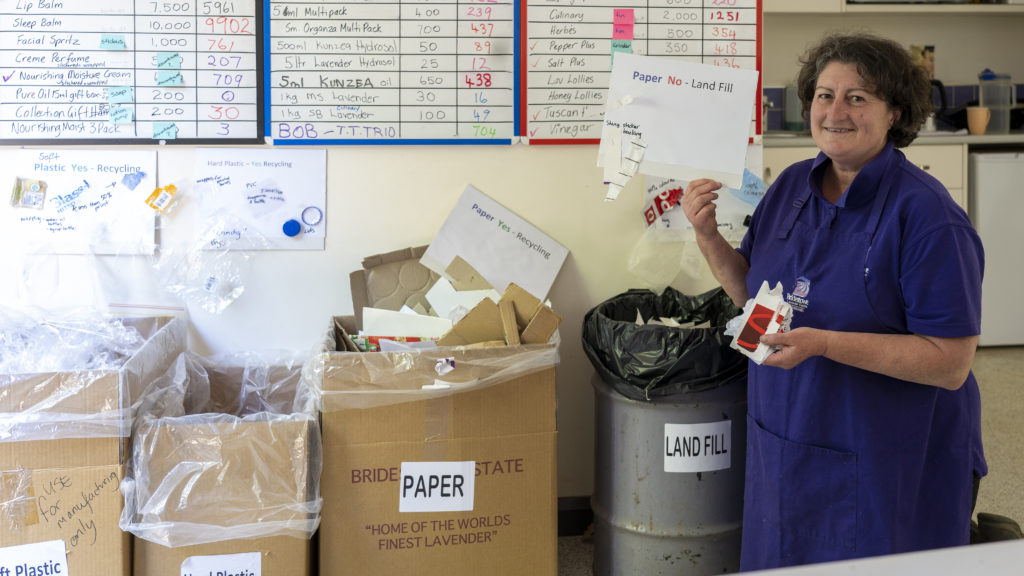

Introduce procedures for sorting and separating waste in-process to keep material streams as free from contaminants as possible. Think about your responsibility as a producer; what happens to the materials you use in your products and/or services when their useful life is over? Are there opportunities for you to reclaim them and reintroduce them to the system?

As a customer, you can influence your supply chain to support the circular economy. For example, you could ask your suppliers to use recycled packaging, or develop re-usable packaging solutions.

As a supplier, you can educate your customers to help them make choices that support the Circular Economy. This might include offering recycled alternatives and providing information about how to recycle the materials in your products at the end of its useful life.